Can Wire EDM cut holes with precision? This powerful technique uses electrical discharges to carve through tough materials. In manufacturing, Wire EDM is crucial for creating intricate holes that are difficult to achieve with traditional methods. In this post, we’ll explore how Wire EDM works, its capabilities, and why it’s so effective for drilling precise holes in complex materials. We’ll also discuss its applications and limitations in various industries.

Is every shiny metal truly a good conductor? Many think only copper or silver matter in electricity. But molybdenum surprises experts. It conducts electricity, resists heat, and stays strong at extreme temperatures. In this post, you’ll learn why conductivity matters, how molybdenum works, and where its unique properties are used.

Which wire is truly better for modern industries: molybdenum or tungsten? Both metals are strong, heat-resistant, and widely used. Yet, each has unique advantages that affect performance and cost. Molybdenum is lighter and more ductile, while tungsten withstands extreme heat but is heavier and harder to process. These differences make choosing the right wire crucial for aerospace, electronics, and manufacturing. In this post, you’ll learn how these wires compare in strength, corrosion resistance, cost, and sourcing challenges.

Choosing the wrong EDM wire can slow cuts, break, and waste money. So what is EDM wire cutting, and why does material matter? EDM wire uses controlled sparks to shape hard, conductive metals precisely. Common options include brass, copper, molybdenum, tungsten, coated, and steel-core wires. In this guide, you’ll compare EDM wire types and EDM wire properties to find the best material for EDM wire.

Have you ever wondered how industries cut tough metals? Molybdenum wire holds the answer. It is a strong refractory metal used in many fields. Its high melting point and corrosion resistance make it vital today. In this post, you’ll learn why molybdenum wire matters. We’ll explore its features and key uses across industries.

Can you really wire an EDM with molybdenum? Many machinists still wonder. EDM wire cutting depends heavily on the electrode choice. Molybdenum wire is strong, reusable, and widely used in fast wire EDM. But is it always the right option? In this post, you’ll learn when molybdenum wire works best and where it may not.

Turbine Components: Wire EDM is used to manufacture precision components for wind and gas turbines. The ability to cut hard and durable materials is essential for producing reliable energy equipment.Nuclear Industry: Precision components for nuclear reactors and other critical equipment are often fa

Intricate Designs: Wire cutting is used to create intricate and detailed designs in jewelry making. The precision and ability to work with precious metals make it a popular choice in this industry.

Material Research: Wire cutting is used in research labs to prepare samples and test new materials. The precision and ability to cut a wide range of materials make it a valuable tool in material science research.Innovative Designs: Researchers and engineers use wire EDM to experiment with and develo

Micro-Machining: Wire cutting is used for micro-machining of electronic components, such as connectors and sensors. The ability to produce small, precise features is critical in this industry.Semiconductor Manufacturing: Wire EDM is used to create precise components for semiconductor manufacturing e

Engine Components: Wire cutting is used to manufacture precision engine components, such as fuel injectors and transmission parts. The technology ensures high accuracy and repeatability, which are essential for automotive applications.Custom Parts: Custom and high-performance parts for racing and sp

Surgical Instruments: Wire EDM is used to produce intricate and precise surgical instruments and implants. The high precision and ability to work with biocompatible materials are crucial for medical applications.Medical Devices: Components for medical devices, such as stents and catheters, are often

Component Fabrication: Wire cutting is used to manufacture complex and high-precision components such as turbine blades, engine parts, and structural components. The ability to cut hard materials like titanium and Inconel makes it invaluable in this sector.

Tool and Die Making: Wire EDM is extensively used for creating intricate shapes and fine details in tool and die manufacturing. It is ideal for producing molds, punches, and dies with high precision.Prototyping: The equipment is used to create precise prototypes of parts and components, allowing for

Have you ever wondered how industries cut tough metals? Molybdenum wire holds the answer. It is a strong refractory metal used in many fields. Its high melting point and corrosion resistance make it vital today. In this post, you’ll learn why molybdenum wire matters. We’ll explore its features and key uses across industries.

Molybdenum wire is not the type of wire you see every day. It is usually made from pure molybdenum, with a purity of 99.95% or more. In some cases, small amounts of titanium, zirconium, or lanthanum are added. These alloying elements give the wire more strength and flexibility, making it suitable for tougher jobs.

Molybdenum wire is available in several forms, each designed for different applications. Black molybdenum wire has a rough, oxidized surface and is often used in high-temperature environments. White molybdenum wire, on the other hand, is cleaned through alkaline washing, leaving a smooth, polished surface for applications where appearance and precision matter. Sprayed molybdenum wire is commonly used to coat automotive or mechanical parts, improving wear resistance. Wire-cutting molybdenum wire is perhaps the most well-known form, serving as a key material in EDM machining for cutting conductive metals.

Here’s a simple list of the common forms:

Black molybdenum wire – rough, often used in high heat.

White molybdenum wire – smooth, after alkaline washing.

Sprayed molybdenum wire – coats automotive and mechanical parts.

Wire-cutting molybdenum wire – key material in EDM cutting.

Despite its thin size, molybdenum wire is incredibly strong and stable. It usually comes in diameters ranging from 0.02 mm to 0.2 mm, making it suitable for very precise work. Its toughness and flexibility help reduce wire breakage during continuous operation, which is why it is trusted in industries requiring high accuracy and durability.

| Property | Value / Feature |

|---|---|

| Purity | ≥ 99.95% (pure molybdenum) |

| Diameter range | 0.02 mm – 0.2 mm |

| Precision | High, suitable for EDM |

| Breakage rate | Low, stable during cutting |

| Surface types | Black, White, Sprayed, Cut |

Molybdenum wire is prized for its unique traits. Its melting point exceeds 2600°C, letting it survive furnaces and other extreme heat where common metals fail. Strong inter-atomic bonds keep it stable under stress, preserving strength at room and high temperatures. It also conducts heat and electricity efficiently, making it valuable for electronics, heating elements, and semiconductor parts. Resistant to wear and corrosion, it lasts in chemical, aerospace, medical, and automotive settings. The wire remains stable under high pressure and heat, avoiding sagging during long-term use. Another vital property is its ability to form hard carbides when alloyed with steel, which greatly improves strength and durability in industrial tools, machinery, and structural components.

| Property | Benefit / Industrial Value |

|---|---|

| High melting point | Works in furnaces, reactors, extreme heat environments |

| Strong inter-atomic bonding | Maintains strength at both room and high temperatures |

| Thermal & electrical conductivity | Efficient for electronics, heating elements, semiconductors |

| Wear & corrosion resistance | Durable in chemical, automotive, and aerospace settings |

| Stability under stress | No sagging under high pressure and long-term use |

| Carbide-forming ability | Enhances hardness and durability of steel alloys |

Molybdenum wire is widely chosen for high-temperature work because it can survive where other metals cannot. It handles extreme heat inside furnaces and reactors, providing a stable heating material that resists melting or breaking down. Engineers use it confidently because it keeps its strength and shape under continuous stress.

In aerospace, nuclear, and chemical industries, molybdenum wire serves as a structural material. It stays reliable even under pressure, making it a trusted option in safety-critical systems. The wire does not sag or deform when exposed to prolonged high temperatures, which gives industries peace of mind.

It also finds its way into smaller but vital parts. Printing pins, nuts, screws, and lamp holders often rely on molybdenum wire for durability. These components need materials that last under heat, and molybdenum fits perfectly.

| Application Area | Typical Uses |

|---|---|

| Furnaces & Reactors | Heating materials, stable under extreme heat |

| Aerospace Industry | High-strength structural parts |

| Nuclear Industry | Safety-critical materials |

| Chemical Industry | Corrosion-resistant components |

| Everyday Components | Printing pins, nuts, screws, lamp holders |

Molybdenum wire plays a big role in modern lighting. It is often used as filaments in incandescent and halogen lamps, where it must survive intense heat without breaking. These lamps depend on it because it remains strong and steady when temperatures climb.

It also acts as lead wires and electrodes in discharge lamps. By carrying electricity efficiently, it helps lamps maintain brightness and durability. Engineers choose it because it resists corrosion and keeps stable connections in high-energy environments.

In aviation, molybdenum wire serves a different purpose. It is built into windshield heating elements on aircraft to prevent ice from forming. Pilots trust it because it provides fast and reliable defrosting during flights, even in extreme conditions.

| Application Area | Typical Uses |

|---|---|

| Incandescent Lamps | Filaments that resist heat and extend lamp life |

| Halogen Lamps | Stable filaments for bright, long-lasting light |

| Discharge Lamps | Lead wires and electrodes for stable conduction |

| Aircraft Windshields | Heating elements for quick and safe defrosting |

Molybdenum wire is a trusted material in the electronics field because it combines strength, conductivity, and stability. One of its common roles is serving as mandrels for tungsten filaments. These mandrels help shape the filaments, and they must remain stable during the high-temperature manufacturing process.

It also supports tube sockets, grids, and other electronic components. Designers rely on it because it provides excellent conductivity and durability under electrical stress. The wire does not corrode easily, so it ensures long-term performance inside delicate devices.

Another key use is as sputtering targets in high-tech industries. They are applied in solar cells, flat screens, and semiconductors, where thin films must be deposited evenly. Molybdenum works perfectly here because it provides both precision and efficiency in the coating process.

| Application Area | Typical Uses |

|---|---|

| Tungsten Filament Mandrels | Stable support during filament manufacturing |

| Electronic Components | Tube sockets, grids, durable connectors |

| Semiconductor Industry | Sputtering targets for solar cells, flat screens, chips |

Molybdenum wire is not only for factories and machines; it also finds an important place in healthcare. Doctors and engineers use it in catheters, surgical tools, and precision medical devices where reliability is crucial. It works well because it can be drawn into very fine diameters without losing strength, allowing devices to stay lightweight and accurate.

Its real advantage comes from being both biocompatible and resistant to corrosion. When inside the human body, it does not react badly or release harmful substances. It also resists damage from body fluids, keeping devices safe and dependable. Because of these traits, patients can rely on tools built using molybdenum wire for delicate medical procedures.

| Medical Application | Role of Molybdenum Wire |

|---|---|

| Catheters | Provides fine, strong structure |

| Surgical Tools | Ensures durability and precision |

| Medical Devices | Safe due to biocompatibility and corrosion resistance |

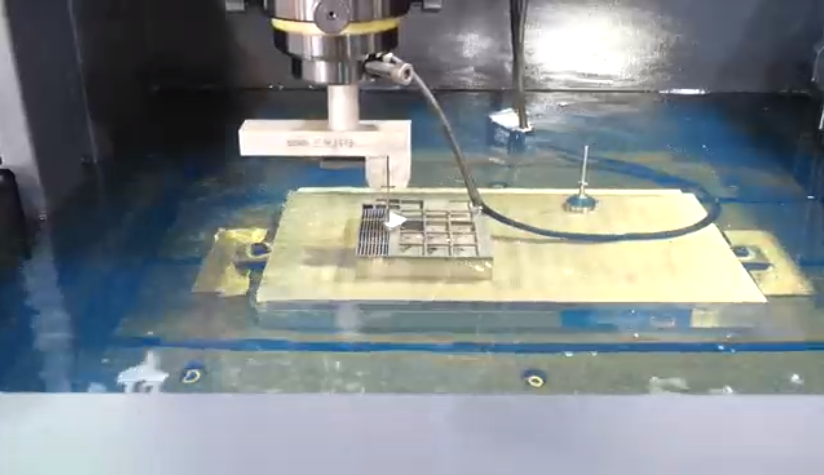

Molybdenum wire is widely used in Electrical Discharge Machining, or EDM. The working principle is simple but powerful: when the wire and workpiece are connected to electricity, a pulse discharge happens between them. This creates instant heat reaching thousands of degrees Celsius, which melts or even vaporizes small areas of metal. Because of this, EDM can cut through very hard materials without needing physical pressure.

An insulating liquid is always present during the process. It stops short circuits from forming, clears away tiny debris, and cools the electrodes at the same time. Without it, the wire and workpiece would quickly fail. The liquid also helps restore the gap between the wire and the material after each pulse.

This method works well on many conductive materials. Engineers often use it to cut steel, aluminum, brass, titanium, and even superalloys that are difficult to shape by other methods. The wire’s strength and stability make it possible to keep cutting for long hours without frequent breaks.

The biggest advantages are clear: fast processing speed, high accuracy, and continuous long-time operation. EDM using molybdenum wire delivers smooth finishes and complex shapes that traditional cutting tools cannot easily achieve.

| Feature | Description |

|---|---|

| Working Principle | Pulse discharge melts or vaporizes metal instantly |

| Role of Insulating Liquid | Prevents short circuits, removes debris, cools electrodes |

| Suitable Materials | Steel, aluminum, brass, titanium, superalloys |

| Advantages | Fast speed, precision, continuous long-time operation |

Molybdenum wire is also important in the automotive field, especially when it is used as a spraying material. Engineers apply sprayed molybdenum wire onto surfaces of high-wear components like piston rings, gearbox synchronizers, and gear selector forks. Once sprayed, it forms a thin, protective layer that bonds firmly to the base metal. This coating gives car parts extra strength and allows them to withstand heavy use over time.

The coating not only increases durability but also provides strong wear resistance. Drivers may never notice it, yet it keeps critical parts working smoothly even under constant friction. Another benefit is the lubrication performance it offers. The sprayed layer reduces friction between moving parts, helping vehicles run more efficiently while extending the lifespan of components.

| Automotive Component | Role of Sprayed Molybdenum Wire |

|---|---|

| Piston Rings | Wear resistance, long service life |

| Gearbox Synchronizers | Smooth operation, reduced friction |

| Gear Selector Forks | Protective coating, improved durability |

Molybdenum wire is gaining attention in additive manufacturing. In 3D printing, it is chosen for building high-temperature components that must resist heat and stress. Engineers rely on it because it maintains structural integrity even after repeated heating cycles. This makes it a valuable material for aerospace, energy, and industrial parts.

It is also widely used as an electrode wire in welding and glass melting. When exposed to intense heat, it stays stable and conducts electricity smoothly, which ensures clean welds and efficient glass processing. Workers prefer it because it does not deform easily, even under heavy loads.

Beyond these advanced uses, molybdenum wire also supports agricultural and industrial applications. Farmers benefit from stronger tools and machinery that last longer, while industries use it in coating, reinforcement, and specialized equipment where reliability is critical.

| Application Area | Role of Molybdenum Wire |

|---|---|

| Additive Manufacturing | 3D printing of high-temperature components |

| Welding & Glass Melting | Electrode wire for stability and conductivity |

| Agriculture & Industry | Stronger tools, coatings, reliable machinery |

Molybdenum wire does not come in one single form. It can be grouped in several ways, depending on its makeup, how it is made, or where it is used. Each type has specific strengths, and industries select them according to their needs.

Some wires are made from pure molybdenum, usually above 99.95% purity. They offer stability and conductivity for many general applications. Others are alloyed with titanium, zirconium, or lanthanum. These alloyed wires are tougher and more ductile at high temperatures. There are also coated molybdenum wires, often covered with materials like molybdenum disilicide (MoSi2) or aluminum, which improve oxidation resistance.

Different methods create wires with different qualities. Drawn molybdenum wire is made by pulling rods through dies to refine diameter. Sintered wire comes from powder metallurgy, pressed and heated for strength. Annealed wire is heat-treated to gain flexibility, while polished wire is smoothed for less friction and better resistance to corrosion.

The finish changes how the wire looks and performs. Black surface molybdenum wire has an oxidized, rough surface, often used in high-temperature settings where appearance does not matter. White or polished molybdenum wire is shiny and smooth, perfect when precision and low friction are needed. Coated wire has a protective layer, making it stronger against oxidation or wear.

Some wires are built for extreme heat. High-temperature molybdenum wire stays stable above its recrystallization point, resisting sagging during long-term use. Standard molybdenum wire, by contrast, is best for moderate temperature jobs where cost-efficiency matters more.

Industries classify molybdenum wire based on what it does. Wire EDM molybdenum wire is used for precision cutting. Heating element wire powers furnaces and reactors. Electrode wire is chosen for welding and glass melting. Structural wire supports demanding aerospace or nuclear components. Filament wire is used in lamps and electronics. Medical wire is crafted for catheters and surgical devices, where safety and biocompatibility are required.

Molybdenum wire is used in many industries, from lighting and electronics to aerospace and medical tools. Its high strength, heat resistance, and conductivity make it essential in modern technology and daily applications. Industries should consider it for reliable, high-performance needs where durability and precision truly matter.

A: It uses pulse discharges that create extreme heat, melting or vaporizing the metal.

A: It is lighter than tungsten, stronger than brass, and offers stable long-time cutting.

A: Yes, it can be reused multiple times due to its durability and low breakage rate.

A: Insulating liquid, usually deionized water or emulsion, prevents short circuits and cools electrodes.